Recycling Foam

Being an oil and chemical based product foam is not an overly environmentally friendly product. So how can we help to improve the situation?

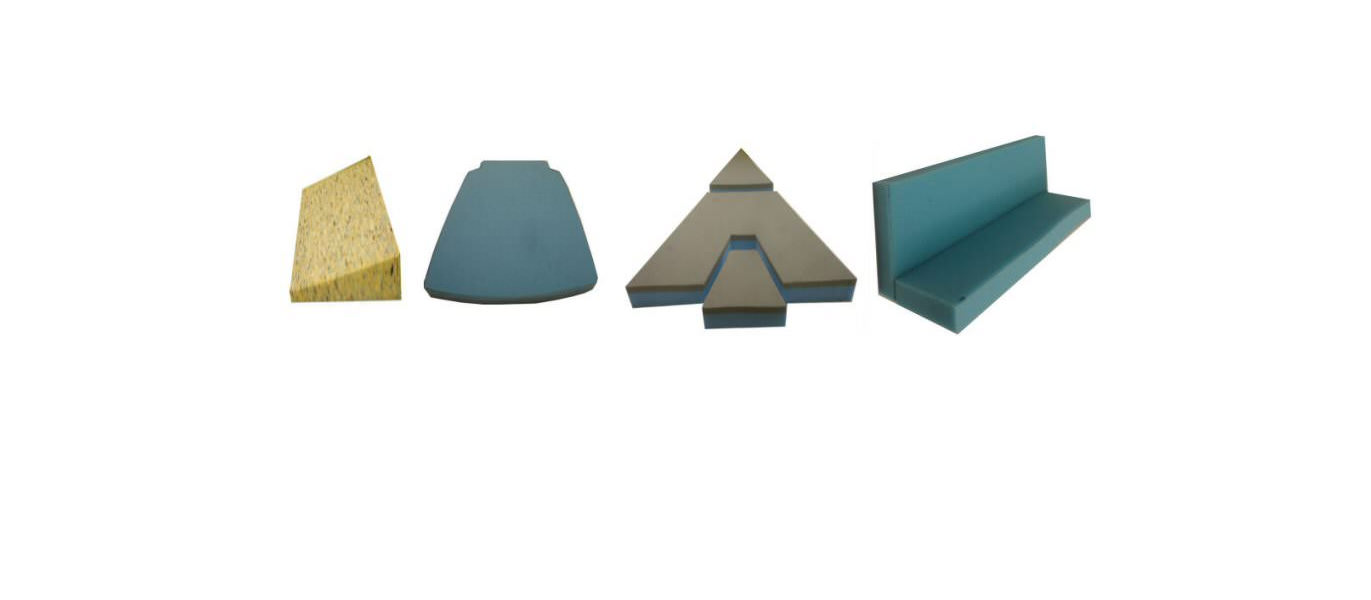

One of the biggest issues with the manufacture of foam cushions is the amount of waste left over after the cushions have been cut from the blocks of foam. Foam is manufactured in large blocks measuring around 2m x 2m x 1m. These blocks are then split in to sheets of the required thickness and then those sheets are cut in to the customers cushion sizes. This does often mean that we end up with odd shaped pieces that are too small for use as a cushion pad. Foam can be bonded together to make a larger piece that is useable but most customers prefer, if possible not to have a join in their foam cushions. Sometimes this cannot be avoided, for instance if the size of the cushion is more than the size of the blocks of foam, but we digress about what happens to all the waste pieces.

We at Jordans Foam have several methods of using the foam offcuts so that they do not go to landfill sites. One way or another every piece of scrap foam we have gets used. Firstly we sell bags of foam offcuts; these are used by customers for a variety of purposes when there is not a need to have pieces of foam cut to specific sizes. For instance we have sold it for packaging and for customers to cut in to small pieces to fill leather poufs. We also supply bags of offcuts to charities free of charge. However we produce far more offcuts than we can use in those methods so most of our scrap foam goes for recycling.

The foam we send for recycling gets cut in to very small pieces which is then re-used as 'crumb foam' which is used in a lot of garden furniture cushions or the small pieces get bonded together in large blocks to make Recon (re-constituted) Foam. The Recon Foam is a very firm foam and is used extensively in commercial seating applications. We then buy the Recon foam back from the suppliers.