Replacing Caravan Cushions

In recent years there has been a trend away from buttoned cushions for caravans to a design that has a T bar in the cover that gives the cushion a shaped appearance but without buttons. This design of cover means that a normal rectangular block of foam cannot be used as sections need to be cut into the foam to allow for the insertion of the T bar.

.jpg)

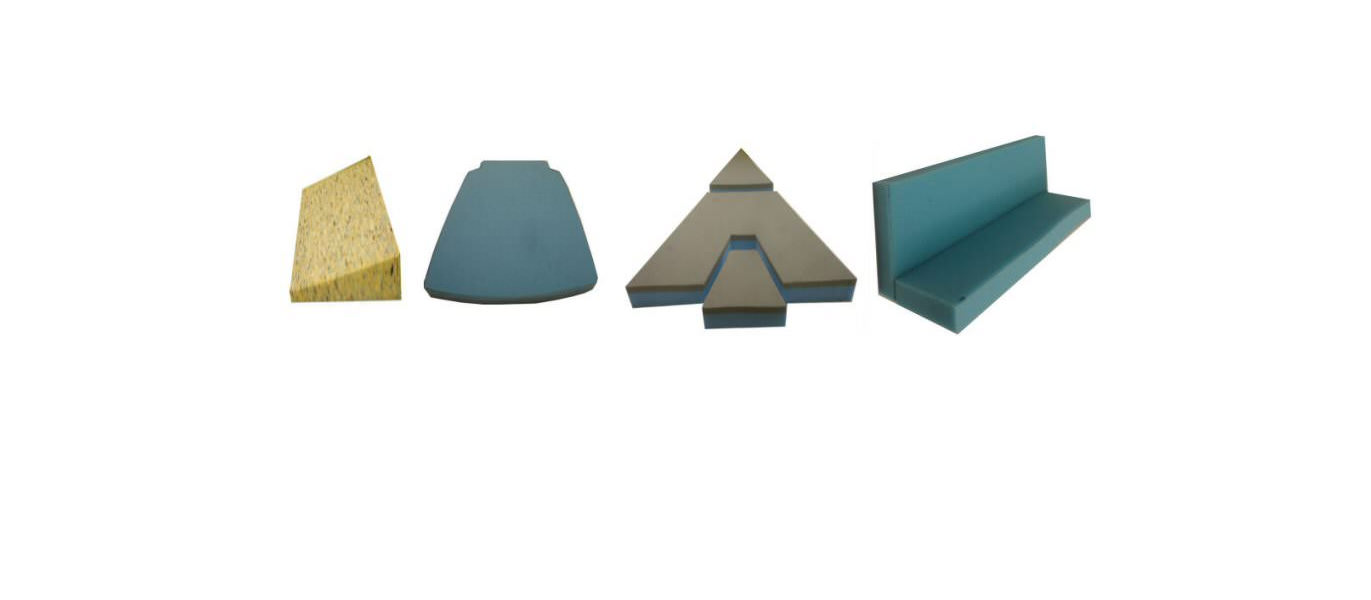

All profile sections bonded to the base foam

Now if the original foam in this new design of cushion were to everybody's taste there would not be a problem but unfortunately, we have had customers come to us who have either found their original cushions uncomfortable or the lifespan of their cushions has been very short.

In all cases we have managed to solve their problems and using our high-quality long-lasting foams we will have given their caravan cushions many more years of life and comfort. We have found that some of these new caravan cushions have traditional Knee Rolls whereas others are made from various sections but have a flat top face, either way it has not been an issue for us.

Some customers have been happy to have a single grade of foam for their cushions but with a degree of hardness or softness to suit their particular taste whilst others have had our popular laminated foam which gives you the best of both worlds being a firm supportive seat cushion but with a softer mattress topper built into the cushion.

.jpg)

Marking out the base foam prior to gluing

Our laminated caravan cushions are normally more involved than when making a single grade foam cushion and with this new design of caravan cushion they are considerably more complex. The stages in the production of these cushions are as follows;

1. The various profiles for example the knee rolls are cut from our RX Flex topper foam. The ideal depth for this type of foam is around 2"/50mm.

2. As the T bar on the covers is normally more than the 2" of our topper foam we have to bond the profiles onto a firmer foam to achieve the correct height for the T bar to fit under.

3. The bonded pieces for each section are then trimmed to give a smooth edge.

4. The bonded pieces are then bonded on to the base section of firmer foam but great care has to be taken when doing this so as to allow the T bars to fit in place, therefore this base section of foam is marked up with instructions as to where the bonding glue can and cannot go.

.jpg)

Bonding a profile section to a firmer foam

Whilst we can work from a customer’s measurements but such is the complexity of this type of cushion we have found that to ensure a perfect fit we would prefer to work from the existing covers. Customers can either post us their covers or drop them in at our Leamington Spa shop. When we receive your order we’ll be able to advise you of the timescale involved in making the new cushions but it is usually one to two weeks.

.jpg)

Trimming a profile section ready for bonding to the base foam

For further information on Replacing Caravan Cushions or foam cut to size, Contact us on 01926 832775